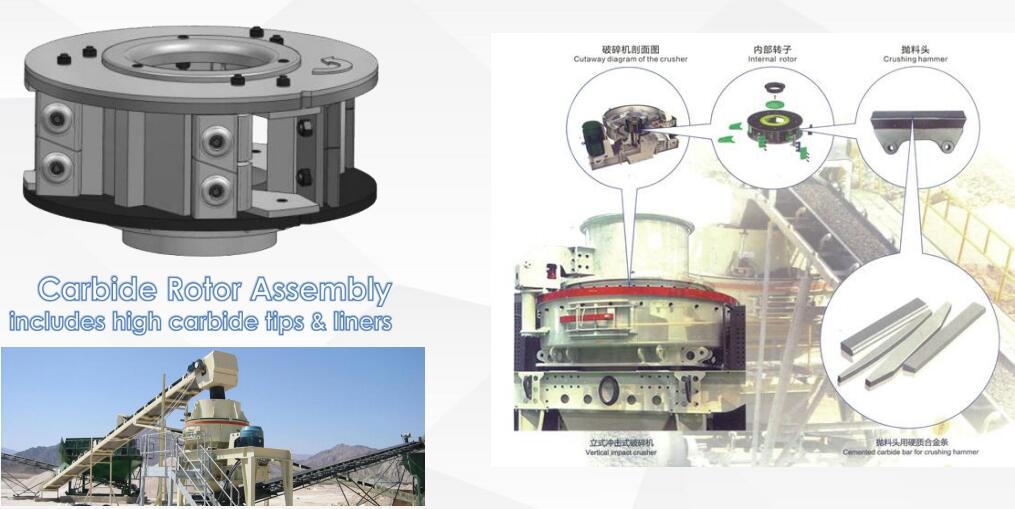

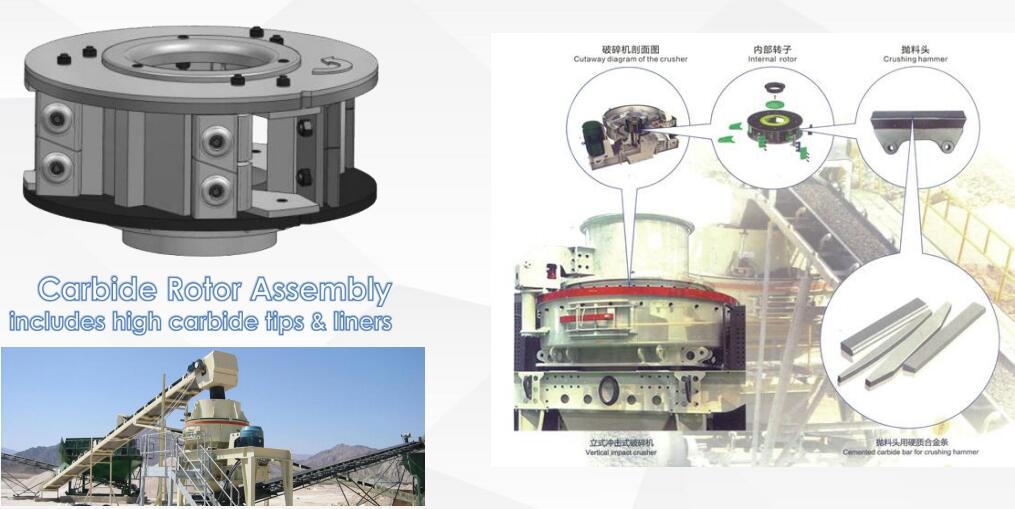

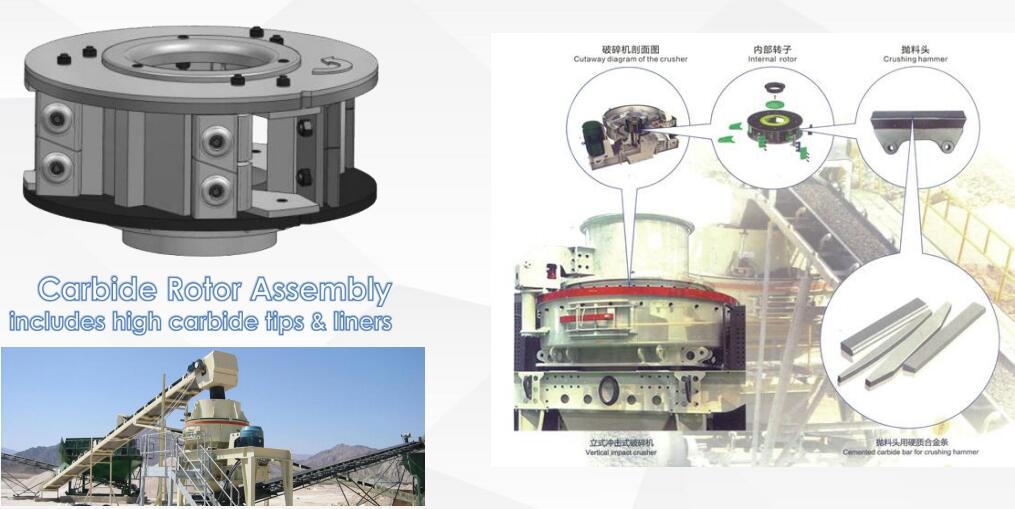

Carbide Bars for Rotor Tips:

The lifetime of rotor tips, back-up tips and trial plate, are mostly decided by the carbide bars, which could bechosen from various carbide grade. Meanwhile, brazing bars with higher hardness is working longer than the bars by gluing.

Wear Parts for VSI Rotors:

Myloo supply all the wear parts for VSI close & open rotors, to fit rotor series of Barmac, Sandvik, Trio, Canica and other brands. Replacing gluing, our carbide parts are cooper brazed by designed tungsten carbide grade to strengthen the wear-resistance and impact.

● TIP SET

● BACK-UP TIP SET

● TRIAL PLATE SET

● CAVITY WEAR PLATE SET

● UPPER&LOWER WEAR PLATE SET

● DISTRIBUTOR PLATE

● FEED TUBE

● FEED EYE RING

● ROTOR FRAME

● ROTOR BOSS

● TAPERLOCK TOP PLATE

● TAPERLOCK

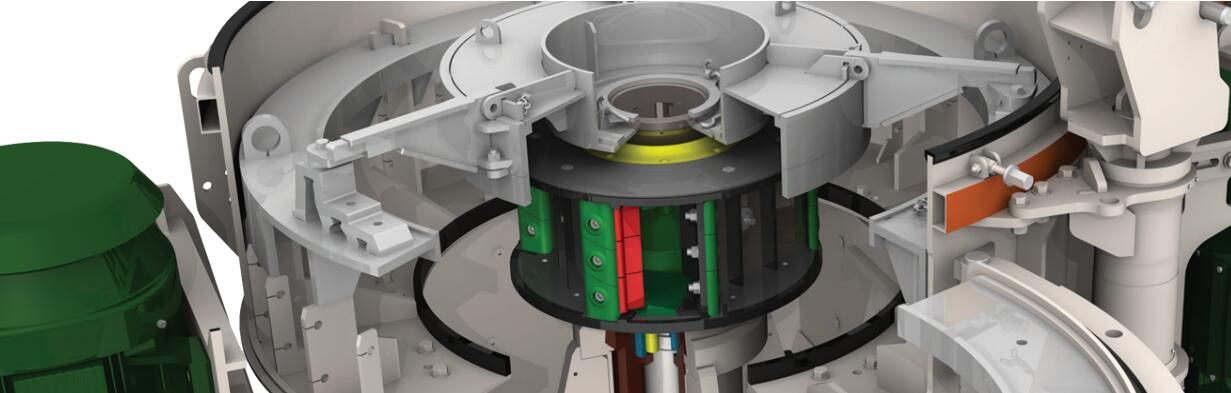

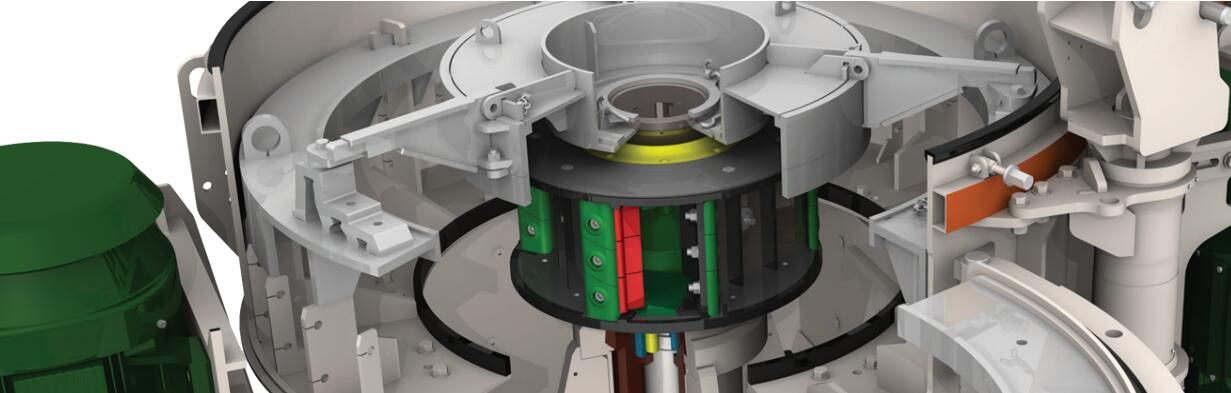

VSI Crusher:

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or Quaternary stage crushing. Unlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rock-on-rock crushing principle, by either striking it with a rapidly moving blow bar(carbide rotor) or by throwing it into a stationary anvil where it breaks upon impact.

VSI crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. It can also be used in the final stages of the crushing process to shape flat material, shaping or removal of soft stone from aggregate. Generally, Vertical Shaft Impact Crusher used for:

1. Ready-Mix Concrete

2. Artificial Sand

3. Asphalt Mix

4. Base Material for Road Work

Carbide Bars for Rotor Tips:

We supply all sizes of carbide bars for rotor tip's gluing or welding. Please contact us for sizes details.

Wear Parts for VSI Rotors:

Myloo supply all the wear parts for VSI close & open rotors, to fit rotor series of Barmac, Sandvik, Trio, Canica and other brands. Replacing gluing, our carbide parts are cooper brazed by designed tungsten carbide grade to strengthen the wear-resistance and impact.

● TIP SET

● BACK-UP TIP SET

● TRIAL PLATE SET

● CAVITY WEAR PLATE SET

● UPPER&LOWER WEAR PLATE SET

● DISTRIBUTOR PLATE

● FEED TUBE

● FEED EYE RING

● ROTOR FRAME

● ROTOR BOSS

● TAPERLOCK TOP PLATE

● TAPERLOCK

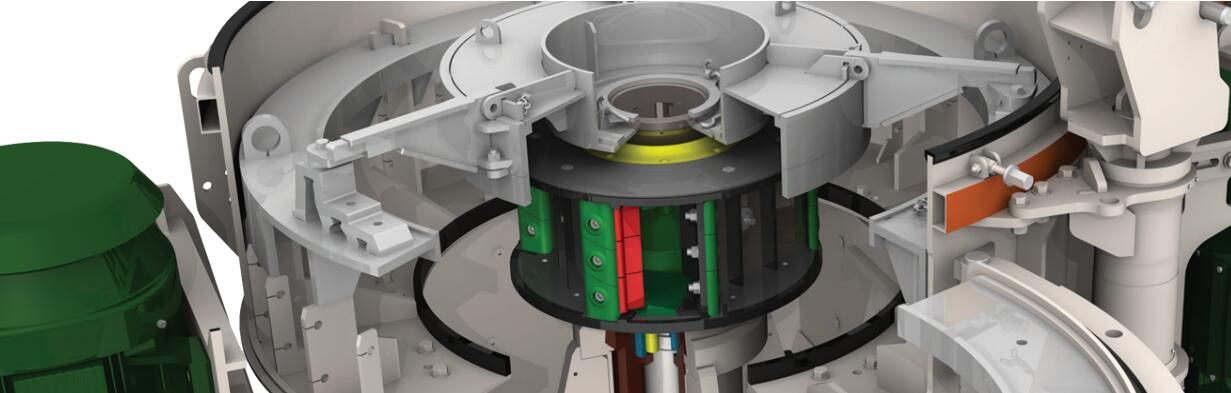

VSI Crusher:

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or Quaternary stage crushing. Unlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rock-on-rock crushing principle, by either striking it with a rapidly moving blow bar(carbide rotor) or by throwing it into a stationary anvil where it breaks upon impact.

VSI crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. It can also be used in the final stages of the crushing process to shape flat material, shaping or removal of soft stone from aggregate. Generally, Vertical Shaft Impact Crusher used for:

1. Ready-Mix Concrete

2. Artificial Sand

3. Asphalt Mix

4. Base Material for Road Work